Not every technician realises that obtaining the correct timing belt tension is only possible on an engine at room temperature. Waiting long enough for the engine to cool down – at least about four hours – is therefore crucial. This is also the case for engines equipped with an automatic belt tensioner.

EXPANSION

All engines expand as they reach operating temperature. The heat makes their height and width expand. This expansion does not affect the performance of the engine, however, there are side effects as far as the tension on the timing belt and the drive system are concerned.

The expansion of the engine block makes the distances between the drive components increase, causing the timing belt to "tighten".

The exact dimensions of an engine at room temperature are known to engine manufacturers. Based on this, they

prescribe the ideal belt tension for a new belt (the engine is at ambient temperature on the engine assembly line). If the installation would take place on a hot engine, the manufacturer cannot provide the ideal belt tension as he does not know the exact engine temperature at that moment. That’s why

tensioning procedures are always developed for cold engines, manual and automatic belt tensioners alike.

TIME TO COOL DOWN

Unless the timing belt is fitted while the engine is at ambient temperature, it is not possible to achieve the correct tension as recommended by the vehicle manufacturer – even if the engine has an automatic belt tensioner. Even if the

pointer of the automatic tensioner was set correctly in the OE prescribed description at installation, it

will no longer be in the correct position as soon as the engine has cooled down. Because of this, the tension can't possibly be correct and the belt will be too slack. So a cold engine is a known constant that you should stick to – always.

DETECTION AND DAMAGE

A

timing belt that has been replaced when the engine is hot, will start to

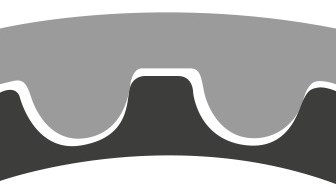

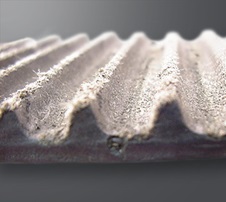

slacken once the engine begins to cool down. Too low belt tension results in less than ideal meshing between belt teeth and pulley grooves (the belt teeth ride high in the pulley due to centrifugal forces). Marks on the belt itself will indicate this clearly. Belt flapping is another common result. The heat generated by the flapping will cause the rubber to harden.

Belt damage results from insufficient belt tension

As a result, if the timing belt is changed when the engine is hot the consequences will be devastating:

- Premature wear

- Possible tooth jump

- Tooth shear

- Belt failure ahead of the scheduled duty cycle

- Expensive repair

Conclusion: waiting for the engine to cool down properly can make all the difference between a job well done and a job doomed to fail.