As a result of increasing vibrations inside engine compartments, practically all car manufacturers use torsional vibration dampers (TVDs) or harmonic balancers in their engines to reduce vibrations and increase comfort for the driver. But when a TVD needs replacement there are various types of bolts of which some need to be replaced because of technical requirements and others can be re-used.

To determine which bolts to replace when fitting a TVD, you should always refer to the guidelines prescribed by the supplier. These guidelines are determined based on the strain that the TVDs encounter during fixation. Bolts that encounter elastic, temporary deformation during fixation can be re-used since they regain their original form after stress is relieved. Bolts that encounter plastic, permanent deformation during the installation of the TVD, cannot be used to install a new harmonic balancer since they might break.

To determine which bolts to replace when fitting a TVD, you should always refer to the guidelines prescribed by the supplier. These guidelines are determined based on the strain that the TVDs encounter during fixation. Bolts that encounter elastic, temporary deformation during fixation can be re-used since they regain their original form after stress is relieved. Bolts that encounter plastic, permanent deformation during the installation of the TVD, cannot be used to install a new harmonic balancer since they might break.

Not all bolts are the same

Always decide which bolts to re-use depending on the situation you encounter on the vehicle you are servicing, keeping the supplier’s guidelines in mind. There are

four possible situations you may encounter when working on TVDs:

1. Central crankshaft bolt

Some engines such as PSA 1.6 Hdi use one central crankshaft bolt. This bolt is fixed through the TVD, through the crankshaft sprocket into the crankshaft. These central crankshaft bolts require a considerable torque and several degrees of angle rotation to obtain the correct clamp load. Because of permanent deformation, these bolts are not suitable to be re-used.

Some engines such as PSA 1.6 Hdi use one central crankshaft bolt. This bolt is fixed through the TVD, through the crankshaft sprocket into the crankshaft. These central crankshaft bolts require a considerable torque and several degrees of angle rotation to obtain the correct clamp load. Because of permanent deformation, these bolts are not suitable to be re-used.

2. Multiple crankshaft bolts

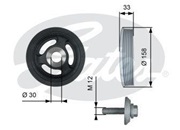

In for example BMW E90 330d engines you will find that the TVD is fixed with multiple crankshaft bolts. Usually 3 to 4 bolts of diameter M10 to M12 are used. They are fixed through the crankshaft sprocket into the crankshaft. These multiple crankshaft bolts are typically not re-usable due to the necessary torque during installation resulting in permanent deformation of the bolt.

In for example BMW E90 330d engines you will find that the TVD is fixed with multiple crankshaft bolts. Usually 3 to 4 bolts of diameter M10 to M12 are used. They are fixed through the crankshaft sprocket into the crankshaft. These multiple crankshaft bolts are typically not re-usable due to the necessary torque during installation resulting in permanent deformation of the bolt.

One package to do the job right

When you decide which bolts to re-use,

always consult the supplier’s guidelines. If you go against supplier's protocol, it is very likely that for example the crankshaft bolt will break during installation when the prescribed tightening torque is applied. Gates offers a wide range of OE equivalent DriveAlign

® torsional vibration dampers that fit the application perfectly and cover all the major models in the market. Our most popular boxes

include all of the required bolts. To avoid wastage, we do not include installation bolts in TVD kits which are already included in the Gates PowerGrip

® kits.