The Mitsubishi 4D56 diesel engine is widespread and has earned popularity among fans of SUVs and pickups worldwide. However, if you don’t provide maintenance when it’s due or if you fail to comply with the installation instructions of the timing drive system, the engine can cause a lot of problems for car owners. Thanks to the presence of an additional synchronous drive of the balancer shafts, as well as the hydraulic tension system of the camshaft drive belt, the maintenance of the Mitsubishi 4D56 diesel engine is not your run-of-the-mill task. In this article, we will not go through the entire procedure for replacing components, since our step-by-step guides are very easily to access (every Gates PowerGrip Kit comes with its own digital installation instructions). Instead, let us dwell on those points where you really need to pay close attention to avoid premature failure of the timing drive.

1. Replace the drive belt of the balancer shafts periodically

First of all, you need to keep in mind that the drive belt of the balancer shafts needs to be replaced periodically. The mileage ranges for recommended timing belt replacement are prescribed by the car manufacturer, but we recommend replacing the drive belt of the balancer shafts every time you replace the camshaft drive belt. We cannot stress enough how important this is. Should the drive belt of the balancer shafts fail, it is highly likely that the debris of the belt will fall into the camshaft drive, and then the car owner won’t get off with just a fright...

2. Don’t economise on hydraulic belt tensioner replacement

Secondly, in order to save money, some car owners prefer not to have the hydraulic belt tensioner replaced. Gates recommends replacing this component each time the belt is replaced, though. After all, there is absolutely no guarantee that the hydraulic belt tensioner will have a longer life expectancy than the belt’s, even if it looks completely functional during inspection.

IMPORTANT:

remove the locking pin ONLY after the pulleys and belt have been installed. After removal, manually rotate the crankshaft two turns and make sure that the protrusion of the hydraulic tensioner rod over the housing is within the 2.3 to 7.6-millimetre range. Read more about handling hydraulic tensioners in our article on the topic.

Only remove the locking pin after the pulleys and belt are installed

3. Mind the tightening torque of the tension roller lever pivot bolt

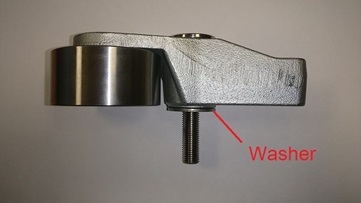

We conclude with a detail that may seem obvious, but that can nevertheless be cause for confusion: the tightening torque of the pivot bolt of the tension roller lever. It should be

between 42 and 56 N*m. Insufficient tightening torque will create insufficient clamping force, which will lead to bending loads on the bolt shaft – which, in turn, can lead to its

fatigue fractures in this component. There’s a washer between the pivoting part of the bolt and the engine block. If the bolt is over-tightened, the washer could be deformed. If that is the case, it will come into contact with the end plane of the hole in the pivoting arm of the tensioner lever and block rotation. The tensioner will not be able to provide the necessary tension and the

wear that the belt receives over 80,000 kilometres will come much earlier.

The washer between the pivoting part of the bolt and the engine block

Mitsubishi 4D56 diesel engine: consequences of insufficient maintenance

When servicing the timing drive system of a Mitsubishi 4D56 diesel engine, there are, in other words, quite a few things to keep in mind. But these are no mere details. In one way or another, all of the above errors lead to premature failure of the timing drive which, in turn, will most likely lead to damage to the elements of the gas distribution mechanism.