When a part from an OE supplier appears to fail at installation, a manufacturing fault is often assumed to be the problem. But faulty parts are, in fact, rare. Intensive testing and an extensive series of rigorous quality checks during the manufacturing process make sure of that. Installation errors, however, are far more likely to be the cause. Take the T43245, the automatic tensioner we designed in association with VAG. Installers at different garages were experiencing the same problem: the adjuster on this tensioner would crack and break during installation. We looked into the problem and discovered that a common installation error was causing the issue. Discover our simple fix that keeps your adjuster from breaking!

T43245: from Audi A5 to Skoda Octavia

Let’s give you a little background on the T43245 first. Together with VAG, we designed this automatic tensioner for a wide number of models in the 1.4, 1.6 and 2.0L common rail TDi diesel engine range. Both the Gates tensioner and the matching Gates timing belt (part number 5678XS) are installed as OE parts in the synchronous belt drive system (SBDS) on popular models such as VW Tiguan, Audi A5 and Skoda Octavia.

Fitting procedure for the T43245 tensioner

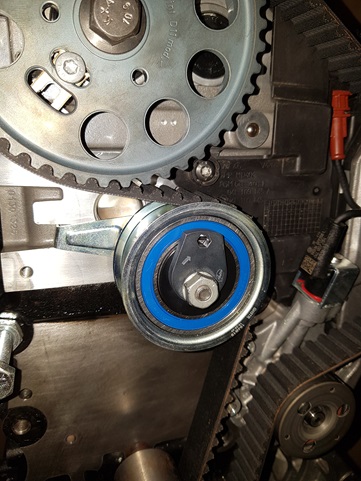

For the full installation guidelines, we advise you to scan the QR code on the Gates PowerGrip™ kit box. In what follows, though, we will walk you through the fitting procedure of the T43245 so that you avoid cracking and breaking the adjuster. The T43245 is an ‘eccentric automatic tensioner’; its round ‘fitting’ hole is found off-centre, rather than in the middle of the tensioner, as you can see on the image below. During installation, the tensioner is adjusted by means of an Allen key.

T43245 with off-centre fitting hole

1. Fit the tensioner on the engine block

Start by placing the fitting hole over the locating stud on the engine block.

2. Adjust the pointer

While adjusting the pointer, the locking nut (see the image below) must not be too tight. It should only be “finger tight” – to quote the fitting procedure. This is absolutely crucial, as will become clear further on.

Tensioner secured by nut (finger-tight!)

3. Set the correct tension

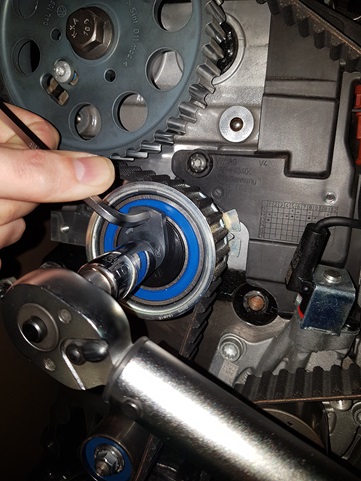

Rotate the adjuster with the Allen key to set the correct tension. The correct tension has been set when the pointer is in the centre of the window.

Hold the nut in position with an appropriate tool to prevent movement.

Setting the correct tension

Where do things go wrong?

Installers who have cracked the adjuster did so soon after turning the Allen key (to move the pointer towards the ideal position). While they subsequently reported the tensioner as faulty, our investigation into the parts they used revealed that, in each and every case, they had secured the locking nut too firmly. Consequently, it rotated together with the adjuster, as the Allen key was turned, thereby putting a clamp on the adjuster. The resistance mounted, until the adjuster gave way and cracked. Fortunately, this situation is easy to avoid, as we explained during the procedure above – you just need to take great care not to screw the locking nut too tight and to hold the nut in position while setting the correct tension.