There is no doubt that internal combustion engines produce vibrations. Vibrations have increased as engines have evolved for a variety of reasons, such as:

- Lower idle speed

- Faster power delivery

- Higher torque

- Downsizing

- Lighter and lighter engine parts (crankshaft, pistons, connecting rods, etc.).

These vibrations must be controlled in some way, not only to increase the comfort of the vehicle occupants but also to prolong the life of the engine components, which is why torsional vibration dampers were introduced on the accessory belt side.

How do vibrations occur?

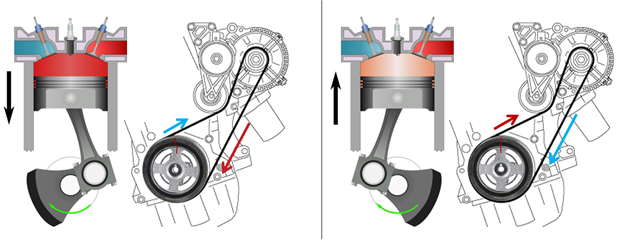

It must be considered that in the duty cycle of an engine there is a power stroke which accelerates the rotation of the crankshaft and a compression stroke which, together with other internal engine frictions, decelerates the rotation of the crankshaft.

In addition to the fact that each piston stops twice per revolution (once at top dead center and once at bottom dead center), the constantly fluctuating torque on the connecting rods causes the crankshaft to flex, causing torsional and axial vibrations constantly.

How is the engine affected?

Without their damping effect, the vibration would be transmitted through the accessory belt drive system and can lead to premature failure. It is also worth noting that as the timing belt is also attached to the crankshaft, a malfunctioning harmonic balancer would also have adverse implications for the synchronous belt drive system. So, replacement is required when the harmonic balancer is no longer able to provide a reduction of vibrations due to wear, You can see here how to change the TVD pulley in 8 easy steps.

Picture description:

- Power stroke (piston accelerates and bends rod)

- Compression stroke (piston slows down and bends rod)

How to control them?

Crankshaft vibrations depend on the rotational speed, being more present at idle speed and in specific rpm ranges depending on the engine, but they also vary depending on the temperature and the engine load. Based on these harmonics of each engine, TVD's are developed to have an optimum operation that eliminates the maximum possible vibrations.

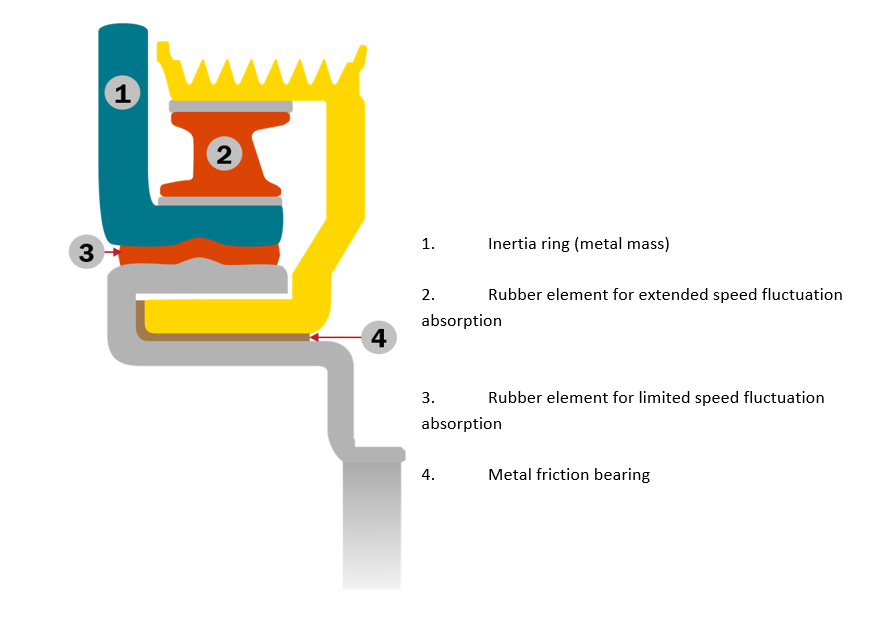

Most of the TVD's have a rubber part which is the best ally to counteract the first-degree harmonics which are the ones that can affect the engine components the most, also the dampers that require it, have an inertia mass in charge of absorbing other types of harmonics which are also important.

Although there are many different types of constructions, we will look at a standard construction that combines two elastomers and an inertia mass,

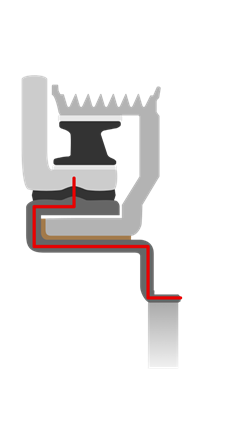

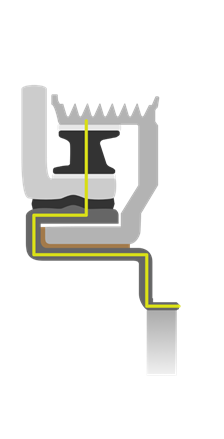

In the bellow image,

- The red line shows the vibration damping from inertia ring and rubber to crankshaft.

- The yellow line shows the speed fluctuation damping from crankshaft to belt contact surface.

Function of metal friction bearing

Under normal load the metal friction bearing is open, if load increases the bearing closes and makes the TVD a temporarily solid pulley. This protects the rubber which is not able to transfer the load.

In case the extra rubber for speed fluctuation absorption wears or breaks, the pulley doesn’t separate but becomes a solid pulley.

Avoid problems during installation and operation

A common failure during installation is not to clean the contact surface between TVD and crankshaft, in this area often remains some rust and dirt, which will cause possible wobbling leading to premature failure.

Also, worth to mention that a TVD never should run without the belt installed. The rubber compound of the TVD has been designed to run with the tension of the belt, without it, the rubber can crack or break, in case of two belt slots in the TVD is also important to run with both belts together to avoid a disbalance which can lead to a premature failure.

To see the most common failure modes of TVD pulleys, we suggest you visit our dedicated Gates Techzone article.

In the accessory belt system, there is another important component to control the vibrations that are transferred, we are referring to the alternator pulley, we have recently published an article about this component so that you can understand it better.

Finally, if you want to know about the importance of a correct maintenance of the accessory system, I suggest you watch our video about it.