Before overrunning clutches were added to the design of the alternator pulley, alternators had a much lower output, a 60 Amp output was already a lot. Nowadays, with more electronics in the car, 60 Amp is less than a minimum alternator capacity. This necessitated the introduction of overrunning alternator pulleys, to protect the belt from premature slip wear. In what follows, we explain exactly how this works.

Lifespan of the auxiliary drive belt

Torsional vibrations are inevitable when the reciprocating motion of an internal combustion engine's pistons is converted into the rotation of the crankshaft. Moreover, the frequency of rotation constantly changes, depending on the operating modes of the engine, and on engine starts and stops. The unevenness of the forces resulting from these two factors shortens the lifespan of the auxiliary drive belt. In addition, the units driven by the belt have their own inertia. As a result, they cannot instantly synchronize their rotation with the rotation of the crankshaft pulley, thereby adding further stresses. At every belt speed variation, the slightest slip causes the belt to wear.

In, particular, modern cars with a large number of on-board electricity-consuming devices, the problem is exacerbated, because the required generator is therefore very big and its rotor has a significant inertia. This combination leads to the following phenomena:

- high loads on the belt, both when the engine is started when speed is increased;

- uneven movements and even slipping of the belt against the alternator pulley.

These phenomena obviously accelerate wear of both the drive belt and of the other drive components.

The overrunning alternator pulley

To minimize these issues, engineers have developed and incorporated an overrunning clutch in the design of the overrunning alternator pulley (OAP). It allows the alternator rotor to rotate freely when the engine decelerates or stops. Anyone who has ever ridden a bicycle is familiar with this effect. When you stop pedaling, the rear wheel does not lock, but continues to rotate freely thanks to a similar mechanism in the rear wheel axle.

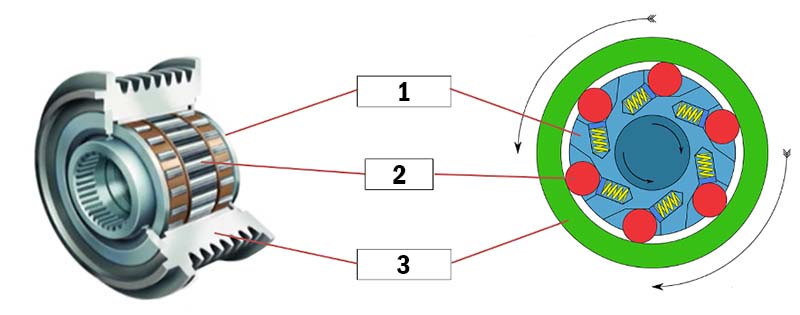

Let's consider the most common variant of this freewheeling mechanism. For simplicity's sake, we can represent the design of the overrunning pulley of an alternator in the form of two rings: an inner and an outer ring. The inner ring is attached to the alternator shaft. The outer ring isn’t fixed to the alternator shaft, but meshes with the drive belt. Between the two parts, in special recesses in the inner ring, there are rollers. The recesses have an irregular profile. If the speed of the outer ring exceeds the speed of the inner ring, the rollers revolve outwards to where their slots are less deep and are caught between the two rings. This locks the two rings together and torque is transferred from the belt to the rotor shaft of the generator. When the engine decelerates and the rotor starts to outrun the engine due to its inertia, and so the rollers return to the deeper parts of their slots. At that point, they are no longer clamped between the two rings, so the inner ring can rotate freely, as the rollers simply revolve against the outer ring, lessening the slip of the belt.

Freewheeling mechanism within an alternator pulley

- Inner Ring

- Roller

- Outer Ring

The overrunning alternator decoupler

When the engine starts up and the RPM rise sharply, another variant of such a clutch can come to the rescue, namely the overrunning alternator decoupler (OAD). It has all the properties described above, but with the addition of a spring or elastomeric damper. In a conventional overrunning clutch, the inner ring can only rotate freely against the outer ring in the forward direction. The presence of an additional damper allows for slight free rotation of the inner ring in the opposite direction. This enables the speed of the alternator/generator to synchronize with that of the belt during start-up as well as in the case of any sudden increases in engine speed.

Replacing overrunning clutches

With all their properties that increase the life of the accessory drive components, overrunning clutches, themselves, are also subject to natural wear and tear and need to be replaced from time to time. The service life of the freewheel naturally depends on the operating conditions, but after 100,000 kilometers, the probability of failure increases significantly. Missing the signs of a malfunctioning overrunning clutch during regular maintenance or diagnostics will result in premature failure of the belt and other units that it is supposed to protect. We have therefore outlined various symptoms of such malfunctions and appropriate diagnostic methods for overrunning alternator pulleys and overrunning alternator decouplers in the corresponding section of the GatesTechZone portal.

Today, an increasing proportion of cars are equipped with overrunning alternator pulleys. It is extremely important to be aware that the different types of pulleys are not interchangeable. For each model, you must select the corresponding product from the catalogue. This is where our online catalogue GatesAutoCat comes in.