These past decades, but especially in the last couple of years, V-belt systems have undergone tremendous technological development. Internal Combustion Engines (ICE) have downsized, while their output and the demands on product performance have continued to increase with the addition of air-conditioning and other comfort systems. This combination creates more rotational forces in the system, meaning that the V-belt has an ever more crucial role to play. To reduce the ensuing vibrations, which are even more prominent at lower driving speeds, automatic tensioners simply don’t suffice; overrunning alternator pulleys, tortional vibration dampeners, and other components must be integrated into the system. We’re zooming in on all these components in a series of articles. The previous one focused on overrunning alternator pulleys, and now we will discuss the Micro-V® belt.

A Micro-V® belt for every application

The ABDS drive, which used to be known as the fan belt, has evolved significantly over time. Because the number of pulleys and the power to be transmitted in the system have increased, a more flexible belt was needed. We now use Micro-V® belts instead of simple V-belts. Micro-V® belts have ‘sidewalls’: they consist of miniature V’s all linked together to guarantee an even load distribution. Another advantage of this multi-ribbed belt is that it saves space in terms of the length of the engine, as a simple V-belt could only handle two pulleys, or three at the very most. What is more: we now have a system of specific Micro-V® belts, adapted to every application. All belts in this range are made of EPDM rubber.

1. Micro-V® Unique Fit

Gates Micro-V® Unique Fit belts are specially designed to meet the needs of unique applications or problematic drives. Special belt constructions eliminate belt noise, reduce tension loss, and solve problem drive applications.

- For these belts, we utilise advanced materials like Aramid (that is also used in bullet-proof vests) and crack and heat-resistant EPDM materials. Some belts contain Aramid cords to limit their stretch; others have Aramid fibres in the compound to reduce wear.

- These belts meet or exceed all specifications from the Original Equipment Manufacturer.

- Some unique belts are reinforced with an increased cord pack. In this case, the cord diameter is smaller, but the belts contain more cords per centimeter width.

Micro-V® Unique Fit

2. Micro-V® Stretch Fit

Stretch Fit Drive Systems demand highly engineered solutions. Gates® Micro-V® Stretch Fit® belts, with exclusive self-tensioning technology, were the first aftermarket belts engineered to fit like a glove and perform properly on these unique stretch fit drive systems. Gates continues to add coverage to this growing market segment.

- Gates engineered tensile cord has the necessary combination of strength and flexibility using advanced polyamide.

- Our patented, highly engineered EPDM belt ribs are extremely resistant to contamination, wear and pilling – just like our normal belts, but the cords are different for the Micro-V® Stretch Fit® belt.

- A specially formulated adhesive literally locks on to the cord, allowing the cord to elongate and stretch, while never losing tension.

- Stretch Fit® belts are single use only, and must be replaced if removed.

Micro-V® Stretch Fit

3. Micro-V® Stop&Start

This reinforced belt is designed for vehicles with a belt-driven stop and start function, ensuring an immediate, quiet, and vibration-free restart.

Micro-V® Stop&Start belt

Micro-V® Stop&Start belt

4. Micro-V®

Finally, the regular Micro-V® belt is an all-rounder designed for the direct replacement of 90% of the belts of the European fleet. This aftermarket engineering solution combines the latest OE technologies such as:

- extra flexibility, easy installation

- durability: resistance to tearing and high temperatures

- a special belt construction eliminating belt noise, reducing tension loss, and solving problem drive applications

Micro-V® belt

Selecting the right Micro-V® belt

Despite their outward similarities, these belts are not interchangeable. We cannot stress enough how important it is always to select the Micro-V® belt prescribed by Gates and to use the correct components. Ask your usual spare parts store for the vehicle data or consult the Gates Autocat catalogue.

Lifespan of Micro- V® belts?

Micro-V® belts will need to be changed according to the manufacturer’s specifications. Every make and model has a recommended mileage interval – most car manufacturers also limit the period.

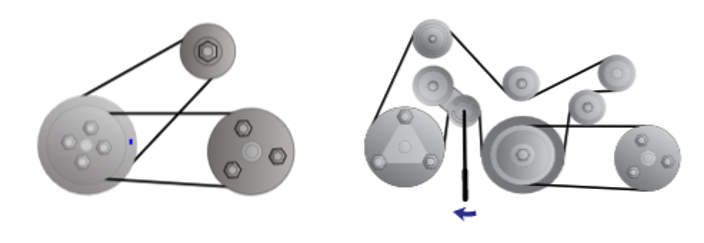

Effect on lifespan of Micro-V® belts: the belt drive has changed significantly. From the simple ABDS drive system on the left, to the more complex system with smaller pulleys and shorter bends on the right.

The tensioner

Not only have Micro-V® belts changed; tensioners have also been upgraded in recent years. There are two kinds of tensioners: mechanical and hydraulic tensioners (with hydraulic fluid providing the dampening in the latter case). The first group can be further subdivided into manual tensioners, where the mechanic provides the prescribed correct tension, and automatic tensioners. Once correctly installed, the latter tensioners automatically adapt to the working conditions and length variation due to wear. In automatic tensioners, the force of a spring guarantees the correct belt tension, while a friction element dampens the spring movement.

The Omega (Sidewinder) tensioner is an example of an automatic tensioner. It is suitable for use in hybrid vehicles or vehicles equipped with a belt-driven stop and start function. In these, the alternator can work as a starter (if certain conditions are met) and/or as a booster to provide additional power.

The Omega (Sidewinder) tensioner