For plenty of modern engines, either the car manufacturer’s installation instructions or the Gates kits specify that the camshaft sprocket must be loose when setting the timing belt. This helps you to get the engine in the correct position (TDC or top dead center) and to get the timing belt’s load distribution right from the very start. In this article we will describe the different procedures and their influence on the load distribution in the drive.

Installation instructions

Almost all newer engines and many of the older ones, too, require you to loosen the camshaft sprocket bolts while setting the timing belt tension. To find out if this is the case, check the installation instructions of the car manufacturer or the Gates PowerGrip™ kit in question. When taking recourse to the latter, you can either scan the QR code on the outside of the box with your phone or enter the code of the package on your PC to get access to all the information specific to the parts inside the box.

Correct course of action

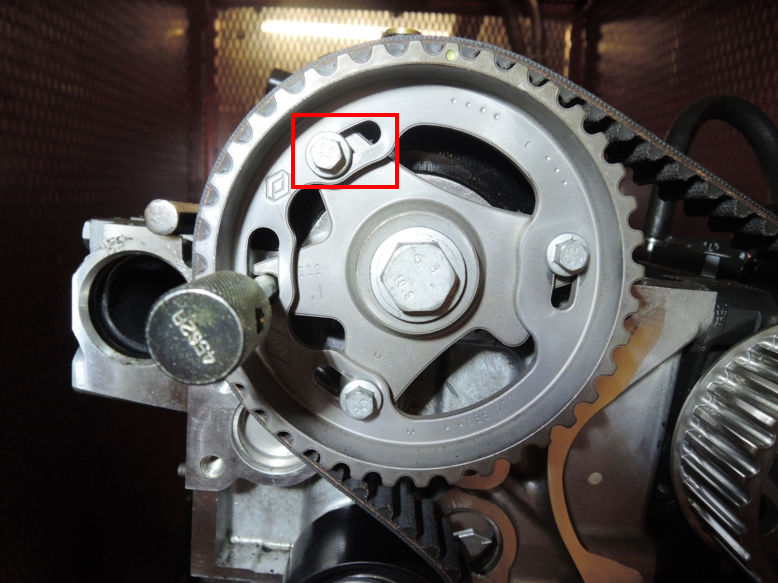

When taking the correct course of action, i.e. when working with a camshaft pulley that is loose, the timing belt can run into the gearing of the camshaft pulley while you set the tension. The camshaft pulley has room to move, because the bolt can slide along the slotted hole, so the belt tension can be transmitted to

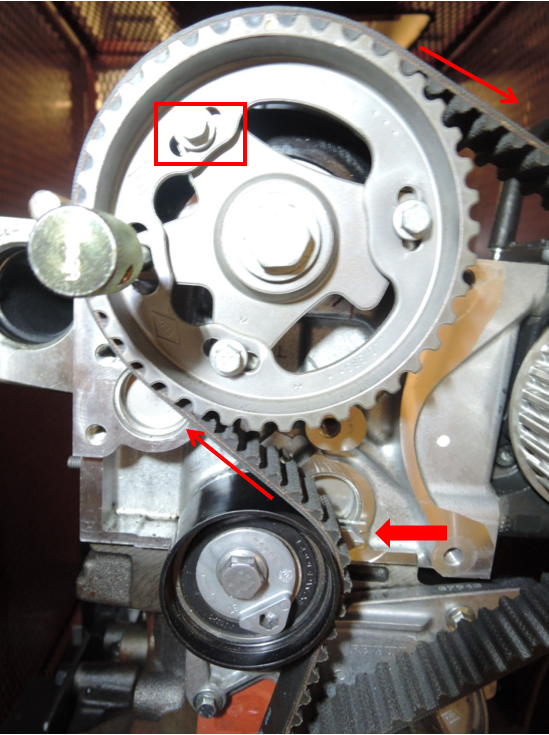

the loaded side of the drive. A look at the pictures below will immediately make this clear. Because the camshaft itself is blocked with a tool, the engine stays in the correct position (TDC).

Camshaft position before setting the timing belt tension

Camshaft position after setting the timing belt tension

Incorrect course of action

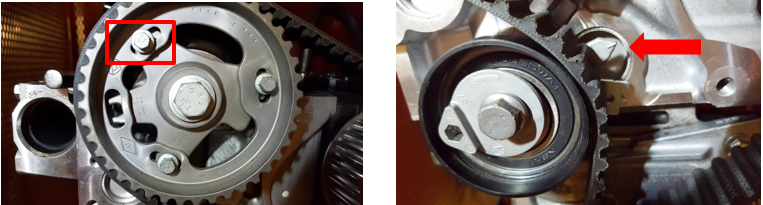

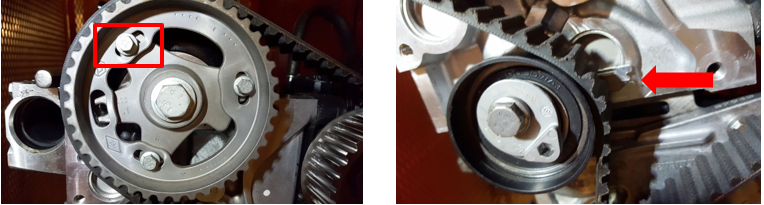

When you do not loosen the camshaft sprocket, however, the timing belt will only have tension on

the slack side of the drive. The loaded side of the drive will not have the correct tension at that moment. Turning the engine clockwise at the crankshaft pulley means that first the belt must be tensioned, and then the camshaft pulley will move. From that moment on, the engine position (TDC) is not exactly right, leading to a

force in the drive that is higher than normal while the engine is running.

Camshaft position before setting the timing belt tension

No change in the position of the camshaft bolt in the slotted hole after setting the timing belt tension

At Gates, we develop our timing belts for use in certain conditions, and if the conditions are not met, the change interval goes down. Also, the engine being off top dead center leads to higher loads in the drive, causing premature engine failure.

On plenty of applications, moreover, the incorrect procedure described above results in incorrect positioning of the tensioner pulley. Since the camshaft sprocket is fixed, the timing belt cannot run into the gearing as it should. This means that the correct pointer position is reached earlier than prescribed, the tension pulley does not move far enough into the drive and is therefore in a geometrically incorrect position on the engine block. This changes the timing belt course and an optimal control function is then no longer guaranteed either.

Important final remark on non-round sprockets

For drives with non-round drive wheels, the wrong approach leads to extreme loads, as such drive wheels have to work in perfect unison.

This topic will be dealt with in a forthcoming article.