The positive crankcase ventilation valve or PCV plays a crucial role in vehicles with internal combustion engines, because it helps the engine deal with the so-called blow-by phenomenon. However, the system being so simple and requiring minimal maintenance means that it is often overlooked, leading to clogged PCV's or oil separators. In what follows, we will highlight the important function of the PCV, describe its components and how it works, as well as the most common problems that may arise with this component.

Blow-by gases generated by internal combustion engines

During the operation of internal combustion engines, mainly in the compression and power stroke phases, there is a small but inevitable passage of gases past the piston rings that is called the blow-by phenomenon. During the compression phase, blow-by gases are intake gases mixed with hydrocarbons, while after the explosion of the power stroke phase, the blow-by gases can also contain some exhaust gases.

Blow-by gases end up in the crankcase housing, where they increase the pressure. The extraction of these vapours is essential for several reasons:

- The presence of hydrocarbons in the blow-by gases causes premature degradation of engine oil.

- The moisture that is deposited in the crankcase as the engine cools is circulated by the pump and can affect lubrication or cause lubrication failure in certain systems and locations.

- Engine performance decreases, as the excess pressure hinders the piston’s downward movement.

- The pressure could eventually even blow out seals and gaskets, causing oil leakage.

The extraction of blow-by gases: 3 crucial components

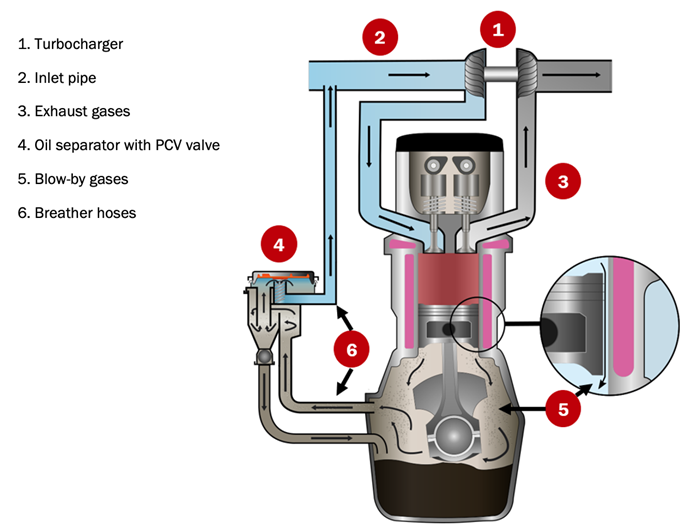

For a successful extraction process, the extraction tube, the PCV and the breather hoses are the most crucial parts.

- Extraction tube: in naturally-aspirated or non-turbo vehicles, the extraction tube is connected to the intake manifold. In turbocharged vehicles, by contrast, the extraction tube is placed on the inlet to the turbo.

- PCV: the positive crankcase ventilation valve is responsible for extracting the blow-by gases from the crankcase or regulating the passage of these gases. In order to do this, the PCV takes advantage of the vacuum that is created in the air intake pipes when the engine is running.

- Breather hoses: the gases are transported through the breathing pipes or breather hoses of the engine.

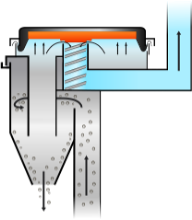

This is a schematic overview of the process described above for turbocharged vehicles:

The extraction of blow-by gases in turbocharged vehicles

Zooming in on the PCV or positive crankcase ventilation valve

1 - General introduction

The PCV regulates the pressure to bleed the crankcase of blow-by gases. By conducting away the blow-by gases, the pressure-regulating valve reduces the vacuum effect in the crankcase. This prevents damage to the engine seals (which could be blown out if the pressure gets too high).

Because the PCV system draws air and exhaust gases into the intake manifold, it has the same effect on the air-fuel mixture as a vacuum leak. This is compensated for by the

fuel injection system. Consequently, as long as everything is working properly, the PCV system has no net effect on fuel economy, emissions, or engine performance.

Today's positive crankcase ventilation valves are built differently from the old metal valves, although their principle of operation is similar.

Old PCV New PCV

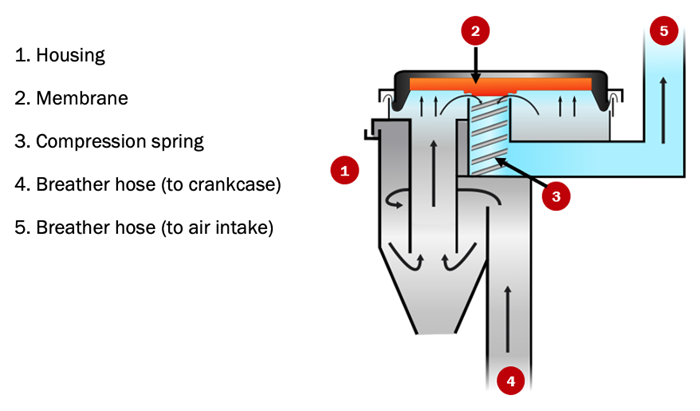

2 - PCV: main parts

The PCV system consists of five main parts, represented schematically below:

PCV system: main parts

3 - The valve diaphragm

Under low vacuum in the intake system piping, or when the pressure of the crankcase gases increases, the valve diaphragm opens, allowing the crankcase gases to pass into the intake.

When vacuum is building in the intake system, the diaphragm closes and interrupts the flow of gases from the crankcase to the intake system, thus avoiding the problem of too much vacuum in the oil pan.

The valve diaphragm (closed)

4 - The oil separator

In the case of high oil temperatures and high engine revolutions per minute (RPM), an oil mist tends to be generated. This mist circulates through the engine breather pipes and the PCV, generating carbon in the intake system and the combustion chambers. That is why many vehicles contain an oil separator. This part sits before the PCV and serves to condense the oil mist and return the oil droplets to the crankcase, preventing them from entering the intake, thereby generating less carbon deposition.

The oil separator

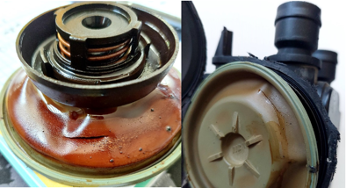

5 - Common failures: clogged PCV or oil separator

Though the PCV system is generally considered trouble-free, a clogged PCV or oil separator is a fairly common problem. A build-up of oil and fuel sludge deposits and/or sludge inside the PCV or decanter can restrict or even block the flow of the vapours. A clogged or restricted PCV cannot draw moisture and vapours from the crankcase. This can result in a build-up of engine-damaging sludge as well as an increase in pressure that could force oil to leak through gaskets and seals.

A clogged PCV hose will also create excessive pressure in the crankcase that can lead to other system failures. For example, if the pressure in the crankcase is too high in turbocharged applications, it will transfer to the turbocharger oil return line. Turbocharger oil drainage is difficult, and the oil will escape from the side of the turbine, thereby increasing oil consumption. Consequently, it also becomes difficult to renew the oil that lubricates the turbo shaft. This oil ends up burning and the shaft becomes damaged due to the lack of lubrication.

Another fault occurs if the valve becomes permanently open, either because the internal membrane gets stuck in this position or breaks. The result is an excessive, uncontrolled flow of air through the pipes, creating an unstable idle, starting difficulties or even engine misfires. Lambda-probe injection vehicles detect any change in the air-fuel mixture and will compensate for it by increasing or decreasing the short and long term fuel trim (STFT and LTFT). Small corrections do not cause problems, but large corrections will produce a lean mixture and a direct trouble code (DTC), while turning on the malfuction indicator lamp (MIL).

The malfuction indicator lamp

If the valve remains open for a long time, the oil vapours that are generated (mainly) at high revolutions can enter the intake manifold, where they condense. The consequent combustion of engine oil will generate white smoke.

Damage caused by the valve being stuck in the open position

6 - PCV system maintenance is key

Because the PCV system is relatively straightforward and low-maintenance, it often gets overlooked. The common replacement interval for many PCV’s is 100,000 kilometers, yet, in many engines, the PCV never ends up needing to be replaced. The manuals of many recent car models don’t even mention a recommended replacement interval for the PCV, recommending only to ‘inspect’ the system ‘periodically’.

Most PCV’s do, indeed, last a long time, but they can wear out or become clogged, especially if the vehicle owner neglects to regularly change the oil, meaning that sludge builds up in the crankcase.

Evidence of sludge build-up in the crankcase

It is recommended to inspect PCV periodically and replace them if you have doubts about their ability to function correctly. In addition, as we saw in a previous article, many valves have a built-in gas pipe that becomes brittle over time. This is why checking the PCV system should be a standard part of your diagnostic and maintenance routine.