A new range of Gates Belt-in-Oil Kits is available from early 2024. In addition to the timing belt and metals, each box will include additional components such as bolts, seals, and gaskets. These are the parts deemed essential by OE manufacturers for comprehensive system replacement procedures.

Each belt from the belt-in-oil kits range offers significant system enhancements for installers and their garage customers. They provide improved resistance to wear and chemicals, improved belt back resistance and low belt elongation over life (therefore enhanced lifetime safety). The additional parts in each box ensure that mechanics have all the parts for the job and that all parts are covered by the same Gates warranty.

- The reasons behind the belt-in-oil technology evolution

For some time, engine designers and car manufacturers have striven to meet increasingly strict CO2 emissions targets. Since 2020, stricter CO2 emission EC regulations have required OEM passenger car fleets to meet 95g co2/km. The technologies used to overcome emission reduction challenges is called belt-in-oil, but is sometimes referred to as hot-oil-belts or even wet timing belt systems.

Belt-in-oil systems have been mass produced for over 10 years. Consequently, the vehicle park is significant and replacement needs are growing. It’s a change that’s driving up the demand for aftermarket solutions.

The Gates product portfolio includes a competitive Belt-in-Oil Range option for the Aftermarket.

- The benefits behind the belt-in-oil technology evolution

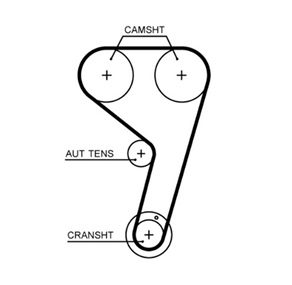

Belt-in oil systems are generally more efficient in comparison to chain driven systems. Here are some of the benefits:

- Lower running weight over pulleys

- Lower elongation over life

- Greater layout design flexibility

![]()

![]()

![]()

- Lower running weight over pulleys

Vibration reductions result in reduction of fuel consumption and engine emissions. meanwhile, timing belt systems in general offer better and quieter operation when compared to chain systems. Weight reductions in belt-in-oil drive systems also contributes more fuel efficiencies at vehicle level.

- Lower elongation over life

Lower elongation for synchronous belts compared to chains. This contributes to reduced fuel consumption over engine life.

- Greater layout design flexibility

Belt and pulley systems allow more engine layout design flexibility for OEMs. At the same time, they remove problems such as drive complexity vs long guides that are created by chain drives. Furthermore, with belts and pulleys, there’s no need for oil spray nozzles. Belt-in-oil system belts are generally between 16-18mm wide. Oil pump belts are around 10mm wide.

- Belt-in-oil part numbering

The Gates range of belts for belt-in-oil systems features part numbers that begin with a T and end with the suffix HOB. This ensures a clear distinction between belts for dry timing belt systems and those for belt-in-oil systems, of which there are two main categories. These are:

- Timing Belts - supplied as a single belt or in various kit formats

- Oil Pump Belts - supplied as a single belt (currently)

For added clarity, part numbers include the following distinctions:

- K0 kits = SBDS Belt + Tensioner

- KP kits = SBDS Belt + Tensioner + Water Pump

Examples of some Gates Belt-in-Oil Range part numbers include:

- T354HOB - synchronous belt = (Ford Applications)

- K01T354HOB - synchronous belt kit = Belt + Tensioner (Ford Applications)

- KP1T354HOB - synchronous belt kit = Belt + Tensioner + Water Pump (Ford Applications)

- T357HOB - oil pump belt (Ford Applications)

- OEMs that employ belt-in-oil technology

Various OEMs are using belt-in-oil technology. These include Ford, PSA Group, VAG Group, Hyundai, and Kia. Some of these manufacturers are installing belt-in-oil belts alongside oil pump belt-in-oil technology. Others are installing just oil pump belt-in-oil technology within their drive systems.

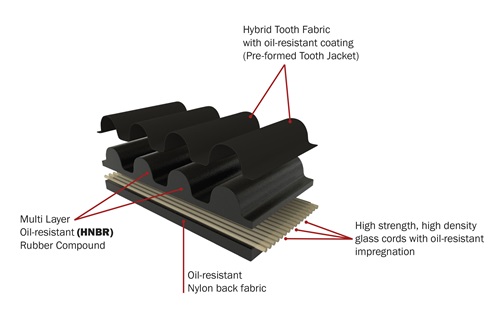

The Gates range of belt-in-oil belts for the aftermarket are manufactured to the same technology and quality standards as the belt-in-oil range for OE installation. Every Gates Belt-in-Oil Range belt is supplied complete with innovative design features to achieve the best possible system performance over life.

The Gates belt-in-oil range for the aftermarket has a yellow and white stripe on the back of the belt. Please note, the stripe IS NOT A TIMING MARK for installation purposes (image 1). This is included for Gates production process purposes only.

Image 1. Gates belt-in-oil: yellow and white stripe

- Internal combustion engines

Internal combustion engines (often shortened to ICE), need oil to cool and lubricate the moving parts and ensure efficient engine operation. However, using the wrong oil specification can lead to incorrect lubricating characteristics. This causes a reduction in engine performance and working life. Oil is generally manufactured using a base oil, refined from crude oil. A variety of additives are then added, such as anti-wear agents, friction modifiers, detergents, rust inhibitors, buffers, and antioxidants. Oil manufacturers have many formulas to ensure the correct oil specification is achieved.

Engine manufacturers spend a lot of time researching, designing and testing engines to be certain that the correct SAE* viscosity rating of oil is selected. The SAE defines the lubrication and performance capabilities of each oil. Selecting a thicker viscosity oil may cause an engine to overwork and therefore, to be less efficient. Selecting a thinner viscosity oil may lead to premature engine wear.

The correct oil with the correct SAE viscosity rating - as recommended by the OEM, must always be used for vehicle maintenance. Always install OE quality specified oil filter(s) to ensure fit, form and function characteristics are not compromised.

- Belt-in-oil systems and oil quality

When engines burn fuel, harmful contaminants accumulate and are captured within the engine oil. Contaminants such as unburnt hydrocarbons (fuel), mix with the engine oil, degrading the oil (over a period of time) that’s contained within the crankcase sump.

If an incorrect oil specification has been used, or the engine maintenance interval specified by the OEM has been overlooked, excessively degraded oil can affect the operation of the belt-in-oil system. For example, causing the belt to swell or it’s condition to deteriorate. This could mean separation of the bonding between the belt teeth, back fabric and high strength glass tensile cord pack. It will eventually lead to catastrophic engine failure.

Other ICE components may also be affected by deterioration of the belt. This occurs when belt debris enters the lubrication system and blocks the oil feed pickups, the VVT solenoid valves, the turbo oil supply pipes and the oil filters. OEM recommended service intervals must be followed. Ensure OE quality specified oils and oil filters are fitted to prevent premature failure.

If the vehicle owner experiences any of the problems listed below, further investigations of the timing belt system and lubrication system will be required:

- Power loss

- Oil pressure warning light illuminates

- Limp home mode activated

- Diagnostic OBD/DTC codes logged in the Electronic Control Unit (ECU)

If the vehicle owner experiences the problems as listed above, it is likely OBD/DTC codes (as shown below) will be logged in the ECU. This will require further investigations of the timing belt system and lubrication system:

- P15A1 - Lubrication system - oil pressure too low in mechanical mode

- P15A8 - Oil pressure fault - coherence with atmospheric pressure (oil pressure too low in relation to the atmospheric pressure)

PSA Petrol 1.0 & 1.2 EB0/EB2 - 3 Cylinder Puretech Engine: – Service Interval Recommended Checks:

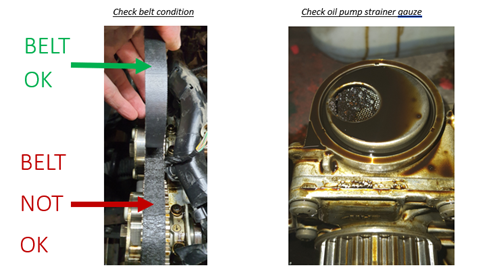

A visual inspection of the belt should be carried out during service check intervals (approx) 12,000 - 16,000 miles (19,000 – 26,000 kms) or every 12 months. The condition of the back of the timing belt can be assessed when the engine oil filler cap is removed. Generally, if the back of the belt is shiny, smooth and black in appearance, without signs of cracking, the belt is in good condition. If cracks are visible, further investigation will be required.

Before proceeding further, it may be worth contacting the OEM to check if there are any outstanding recall or service notifications for the vehicle. Any further investigation and repairs may be covered by the vehicle manufacturer’s main dealerships.

If the back of the belt has a rough textured effect with black patchy sections, and cracks, this is normally a sign that the back of the belt has started to deteriorate. This will cause separation of the belt coating. Oil contamination (as explained previously) is the general cause. In such cases, particles of rubber will be circulating within the oil supply system. If it is not addressed, this may lead to further engine component failure. Further investigation will be required.

The engine oil will need to be drained to allow removal of the crankcase sump. This enables access to assess the condition of oil pump strainer gauze. If there is evidence of rubber belt debris and contamination, it is recommended that the oil pump and belt - as well as any other components fitted - should be replaced.

The Vacuum Pump should also be removed, and the gauze filter located on the rear of the component inspected. If belt debris is visible, braking efficiency may be affected. Therefore, replacement of the vacuum pump unit is recommended.

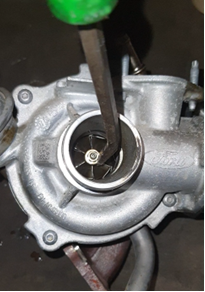

Variable Valve Timing Solenoid Valves (VVT), along with the turbo oil feed pipe, fixing bolt and banjo connector, should be removed, and inspected for any belt contamination. If debris is present, replace the VVT solenoids, clean the turbo oil feed pipework and connection as necessary. Seal replacement is also recommended.

Damaged turbo bearings due to blocked oil feed pipes

As suggested previously, oil contamination may cause the belt-in-oil to swell. Gates Tooling number GAT5249 should be used to check for belt swell. A swollen welling belt can cause failure within the synchronous belt drive system (SBDS).

Gates Tooling number: GAT5249 – should be used to check for belt swell

PSA OE Tooling number: 1643190080

Gates tooling number GAT5249

With the engine oil filler cap removed, the timing belt will be visible. The Gates GAT5249 tool can be inserted through the oil filler cap opening.

If the tool passes over the belt as shown below (image 1), then the belt has not swollen. Please also investigate the appearance of the belt as discussed previously. Check the lubrication system to rule out a blocked oil feed pick up strainer or vacuum pump strainer. The VVT solenoid valves, turbo oil supply pipes or unions and oil filters must also be checked.

If the tool does not pass over the belt as shown in (image 2) then the belt has swollen excessively and will require changing as soon as possible. Please also investigate the appearance of the belt as discussed previously and check the lubrication system for a blocked oil feed pick up strainer or vacuum pump strainer. The VVT solenoid valves, the turbo oil supply pipes, unions and oil filters must also be checked.

After the lubrication system and related components are checked for debris and replaced as necessary, proceed with the installation of the new timing belt and drive system. OE-quality specified oils and oil filters should also be installed.

Check Navigates for all vehicle application requirements https://www.gatesautocat.com/

To summary as main key takeaways

- Always check the vehicle manufacturers current recommended timing belt change intervals. Belt change intervals for some PSA Petrol 1.0 & 1.2 EB0/EB2 - 3 Cylinder Puretech engines have been reduced

- Belt-in-Oil tooling Is only compatible with the vehicle and engine applications as listed within the Product Sheets (Gates T360HOB as well as the OE and competitor equivalent belts)

- Navigates lists Gates Belt-in-Oil Range tooling by vehicle application

- Gates recommends crankcase breather hose inspections for splits, cracks, and blockages (sludge–crimping). Replace as necessary to ensure correct crankcase ventilation

- It is also best practice to replace the Water Pump and Accessory Belt Drive System (ABDS)

- Always install OE-quality specified oils and oil filters

Related News:

Belt-in-oil tooling for PSA: GAT5148A, GAT5249, GAT5255, GAT5257

Belt-in-Oil tooling for FORD ECOBOOST: GAT5150, GAT6160, GAT5252

Gates universal tooling GAT4939

https://www.gatesautocat.com/ (Gates Navigates for your vehicle application requirements)

https://www.gatestechzone.com/en/news/2021-10-vvt-technology-solenoids (Gates VVT Solenoids)

https://www.gatestechzone.com/en/news/2021-06-positive-crankcase-ventilation (Gates Crankcase Ventilation Valves)

https://www.gatestechzone.com/en/news/2020-11-breather-hoses-importance-timely-replacement (Gates Crankcase Ventilation Hoses)

https://www.gatestechzone.com/en/news/2019-05-digital-installation-instructions (Gates Digital Installation Instructions)

How can we help?